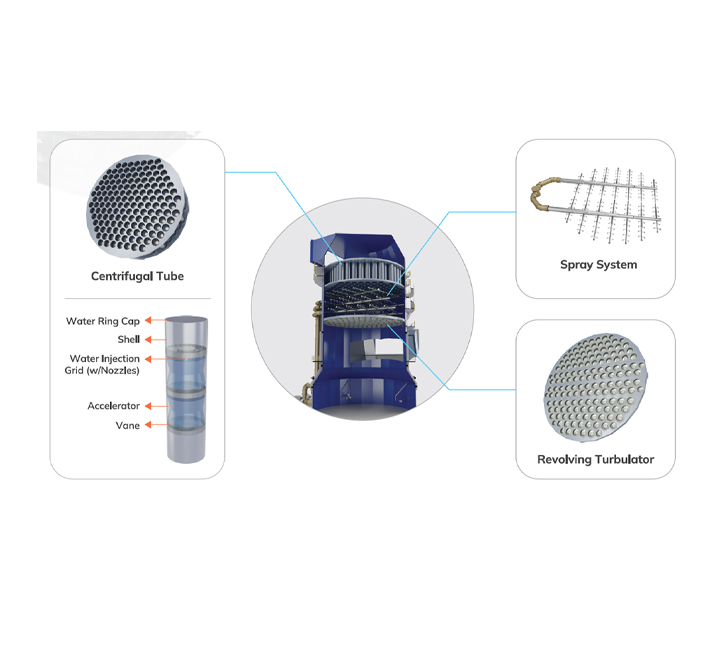

Wet Flue Gas Desulfurization (FGD) System

|

Wet FGD equipment is facility that separates and removes sulfur oxides from exhaust gases emitted from power plants and boilers using absorbents in aqueous solution (slurry).

The 3-D FGD’s unique ability to capture dust inside the absorber (up to 90%) and long-residence time allow power plants to meet new environmental regulations without having to invest in costly upgrades for existing equipment and reduce electricity consumption by 8~15% compared to other FGD systems.

Key Features

-

De-SOx Efficiency > 99%

-

- Meet current & Future Environmental Requirements

-

- Reduce Cost of Operation & Energy Consumption

-

De-Dust Up To 90% or ≤ 5mg/Nm3

-

- No Need for Costly Electrostatic Precipitator Upgrade

-

- Significantly Reduce Dust Carryover

-

- Reduce Maintenance Cost of Downstream Equipment

-

De-Mist ≤ 30mg/Nm3

-

- No Need for Std. Mist Eliminator

-

Smaller Footprint Compared to Mist Eliminator

-

- Lower Construction & Erection Cost

|

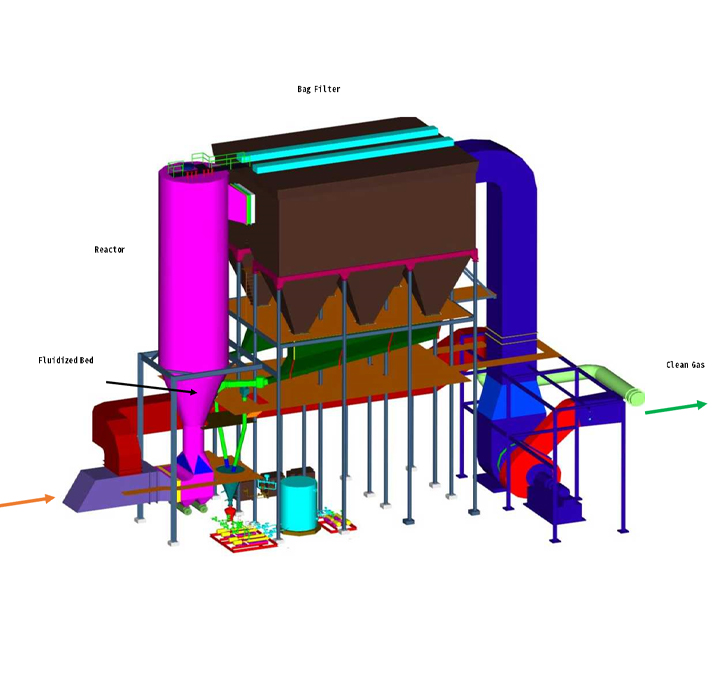

Semi-Dry Flue Gas Desulfurization (FGD) System

|

Semi-Dry FGD System is facility that separates and removes sulfur oxides from exhaust gases emitted from power plants and boilers by spraying lime slurry using atomizer. Flue gas enters the Reactor through several Venturi nozzles to increase gas velocity and support the Fluidized Bed consisting of unreacted and recirculated absorbent lime and recycled fly ash. Flue gas fully mixes with absorbent lime that is hydrated with water injected and atomized separately in the Reactor. Treated flue gas enters the Bag Filter where particulate matter comprising reaction by-products and fly ash is filtered and either recirculated into the Reactor or disposed.

Key Features

-

De-SOx Efficiency Up To 95%

-

- Optimized Heat & Mass Transfer Using CFD Modeling

-

- Meet Current & Future Environmental Requirements

-

Bag Filter Efficiency Up To 99.99%

-

- Able to Operate Independently from De-SOx System

-

Low Upfront Capital & Maintenance Cost

-

- Multiple Emissions Control in One Package

-

- High Reliability and Flexibility

-

Small Footprint & Minimal Noise (≤ 80 dBA)

-

- Ideal Solution for Retrofits Where Space is Limited

|

Dry Flue Gas Desulfurization (FGD) System

Dry FGD System removes sulfur oxides from exhaust gases emitted from power plants and boilers by injecting dry lime ahead of ESP. This is a cost-effective system and suitable for projects with limited water availability and comparatively less stringent efficiency requirements.